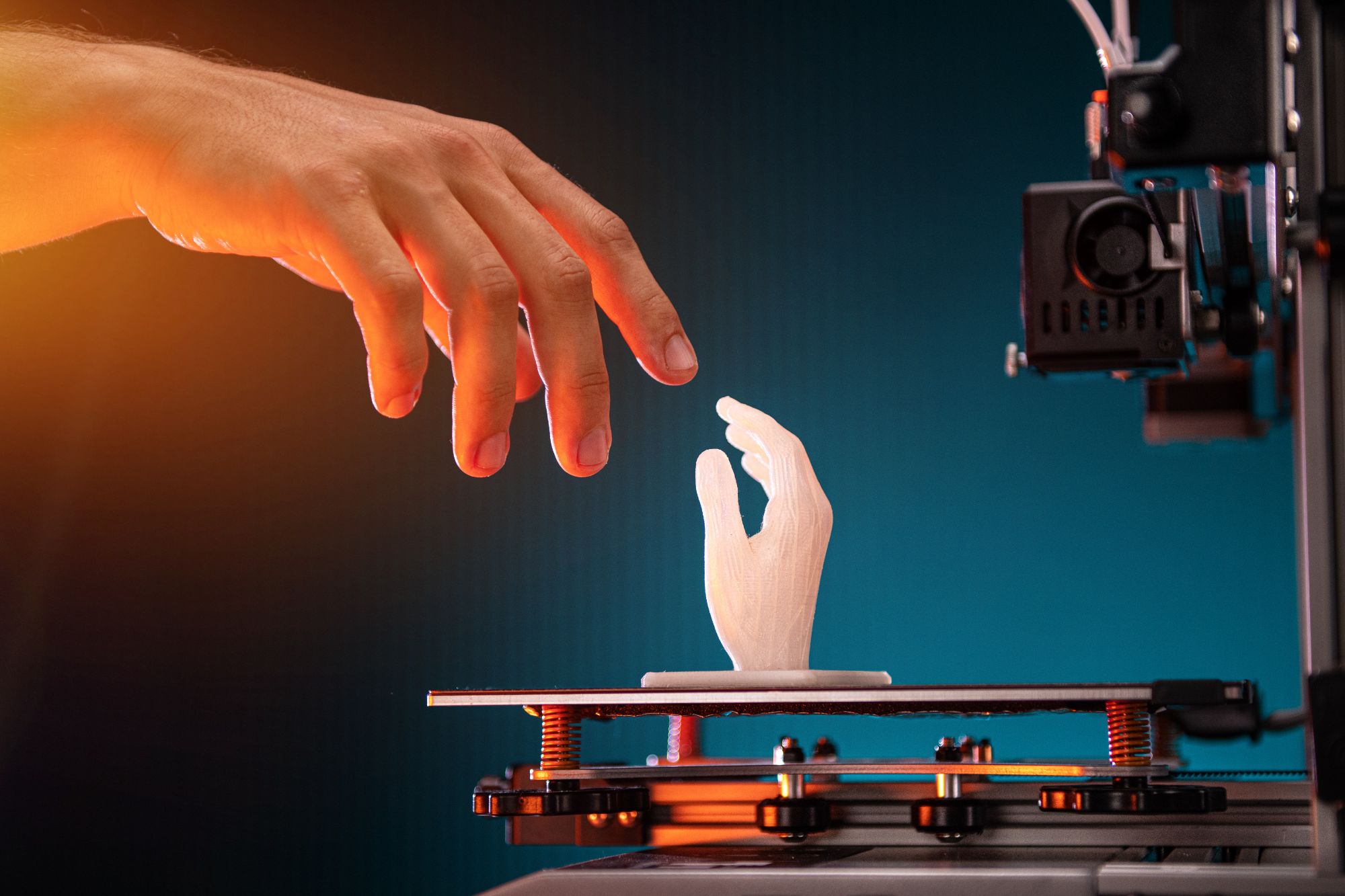

3D Printing Innovations

3D printing, once a niche technology reserved for research labs and prototyping, has evolved into a game-changer across numerous industries. From healthcare to manufacturing, aerospace to fashion, the ability to create three-dimensional objects directly from digital designs has unlocked a new era of innovation. Let’s explore how 3D printing is revolutionizing various sectors and reshaping the future of production and design.

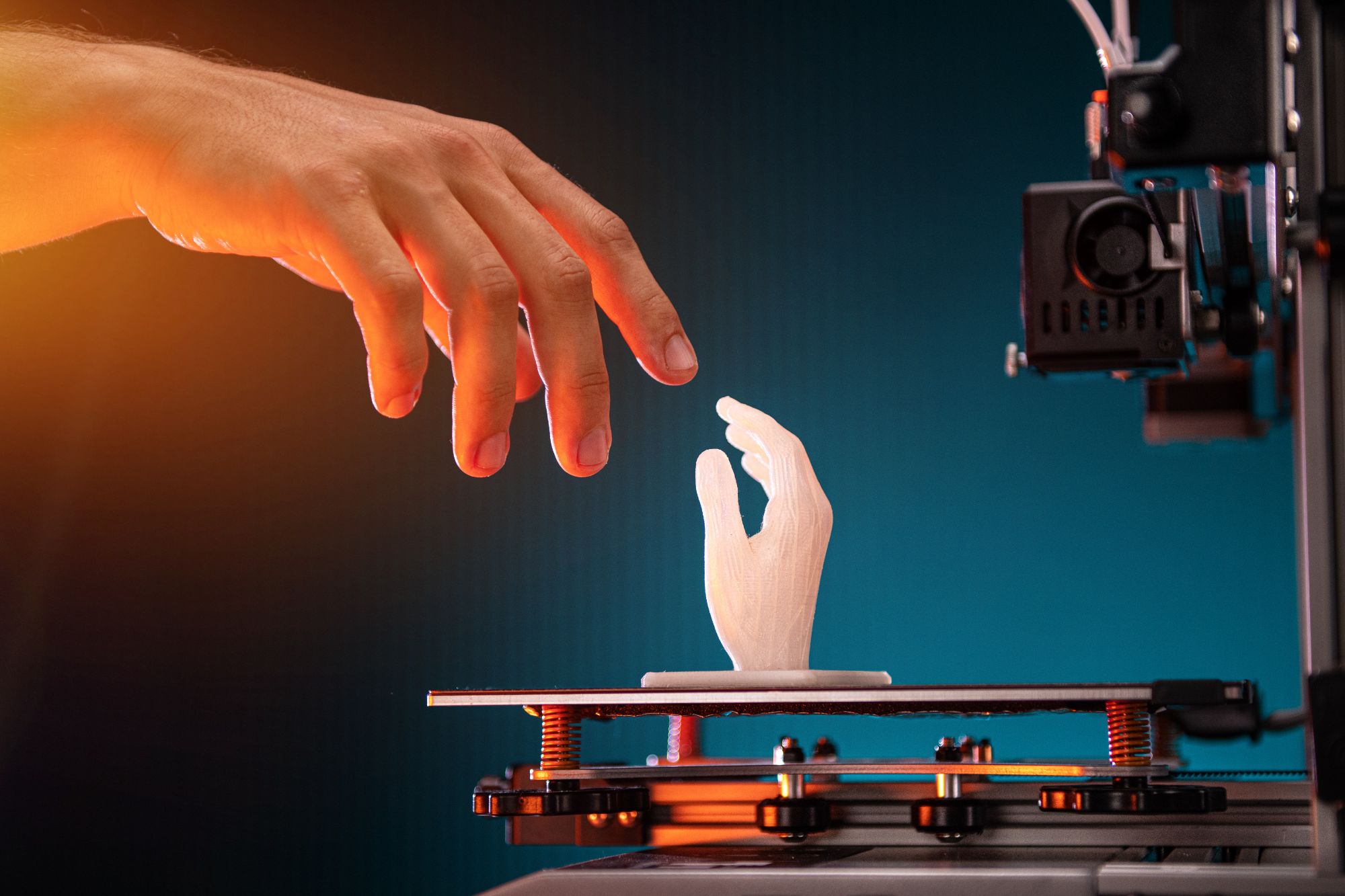

1. Healthcare: Personalized Medicine and Prosthetics

One of the most transformative applications of 3D printing is in the healthcare industry. Traditional medical devices and prosthetics are often generic, mass-produced items that may not perfectly fit a patient’s specific needs. 3D printing, however, allows for highly customized, patient-specific solutions.

- Personalized Prosthetics: 3D printing enables the creation of prosthetics that are tailored to the exact shape of a patient’s limb. These prosthetics can be made more affordable, lighter, and comfortable, while also being more aesthetically pleasing. The precision of 3D printing helps reduce fitting issues, offering patients a higher quality of life.

- Bioprinting: The concept of bioprinting, where tissues and organs are printed using living cells, is also making strides. While the technology is still in its early stages, it holds the potential to create custom tissues for drug testing, organ transplants, and regenerative medicine, significantly improving patient outcomes.

- Medical Implants: Custom implants—such as titanium hip replacements or dental implants—are now being designed and 3D printed to fit an individual’s anatomy, improving functionality and recovery times.

2. Manufacturing: On-Demand Production and Customization

In traditional manufacturing, mass production often leads to waste, long lead times, and high costs associated with custom orders. 3D printing has addressed many of these challenges by enabling on-demand production and rapid prototyping.

- Rapid Prototyping: Engineers and designers can now create functional prototypes in hours instead of weeks. This drastically shortens the development cycle, allowing companies to test and iterate their designs more efficiently before committing to mass production.

- On-Demand Production: 3D printing facilitates the production of small, custom batches of goods without the need for expensive molds or tooling. This has made it easier for manufacturers to meet specific customer demands quickly, offering unique products without the cost of traditional manufacturing processes.

- Supply Chain Disruption: 3D printing is revolutionizing supply chains by allowing parts and products to be printed locally, reducing the need for long-distance shipping and inventory storage. This shift could significantly lower transportation costs and delivery times while reducing carbon footprints.

3. Aerospace: Lightweight, Stronger Components

The aerospace industry is a major beneficiary of 3D printing, using the technology to create lighter, stronger, and more efficient parts for aircraft. Reducing weight in aircraft components can lead to significant fuel savings and lower operational costs.

- Lightweight Structures: 3D printing allows manufacturers to create complex parts with intricate internal structures that are both strong and lightweight. Components such as engine parts, fuel nozzles, and airframe elements can be designed and printed with optimal weight-to-strength ratios, contributing to fuel efficiency.

- Customization for Performance: With 3D printing, aerospace companies can design parts that are tailored to specific functions, improving performance and safety. Customized parts can also be produced on-demand for maintenance and repairs, reducing downtime for aircrafts.

- Reducing Material Waste: Traditional manufacturing methods often involve cutting away material from a larger block, leading to waste. 3D printing, however, uses only the exact amount of material needed, minimizing waste and improving sustainability in aerospace production.

4. Automotive: Custom Components and Rapid Innovation

The automotive industry has also embraced 3D printing for creating prototypes, custom components, and even end-use parts. The technology is enhancing both the design process and the manufacturing of vehicles.

- Prototyping and Testing: Automakers use 3D printing to quickly prototype car parts and test designs before mass production. This process accelerates innovation and allows manufacturers to respond faster to market demands.

- Custom and Lightweight Parts: 3D printing allows for the creation of lightweight, custom parts that improve vehicle performance. For instance, manufacturers are producing custom interior components, engine parts, and even body panels that reduce weight and enhance fuel efficiency.

- On-Demand Spare Parts: Car manufacturers are using 3D printing to create spare parts that can be produced on-demand and shipped directly to customers or service centers, reducing the need for extensive inventory management.

5. Fashion and Textiles: Custom Design and Sustainable Production

The fashion industry has found unique ways to incorporate 3D printing into its designs, enabling both innovative customization and more sustainable production practices.

- Custom-Fit Clothing and Accessories: 3D printing allows designers to create garments and accessories that are customized to the wearer’s body shape, ensuring a perfect fit. For example, 3D-printed shoes, jewelry, and even entire outfits can be tailored to a person’s measurements.

- Sustainability and Waste Reduction: Traditional textile production is resource-intensive, often resulting in a significant amount of waste. 3D printing, however, uses only the material needed to create an item, significantly reducing waste. Additionally, sustainable materials such as biodegradable filaments are being used to print eco-friendly fashion.

- Innovative Designs: Designers are also using 3D printing to explore new design possibilities that were previously impossible or impractical with traditional methods. The ability to create intricate, geometric patterns and textures that move with the body has led to the rise of avant-garde, futuristic fashion.

6. Construction: Building the Future with 3D Printing

The construction industry is beginning to adopt 3D printing for everything from building homes to creating complex infrastructure components.

- Affordable Housing: 3D printing has the potential to revolutionize the construction of homes by reducing labor costs and material waste. Entire houses can be printed on-site, layer by layer, using concrete or other durable materials. This technology could make affordable housing more accessible and significantly reduce construction times.

- Customization and Precision: With 3D printing, architects can create highly detailed and customized designs, enabling the construction of unique, complex structures without the limitations of traditional building methods.

- Sustainability in Building: 3D printing allows for the use of sustainable materials, including recycled plastic, and can minimize material waste. The ability to print structures on-site also reduces transportation costs and environmental impact.

7. Food: Printing Edible Creations

The food industry is exploring the potential of 3D printing to create innovative, personalized, and even sustainable food products.

- Customized Food Designs: 3D printers can be used to create custom shapes and textures for food, offering new possibilities for restaurants and catering. For example, chocolate, pasta, and even pizzas can be printed in unique designs.

- Precision in Food Ingredients: 3D food printers can precisely control the amount of ingredients, allowing for healthier and more tailored food options, such as personalized nutrition or special diets.

- Sustainable Food Production: 3D printing can also use alternative proteins and plant-based materials to produce sustainable food. The technology has the potential to reduce food waste and create food products that are both nutritious and environmentally friendly.

Conclusion: The Future of 3D Printing

The innovations in 3D printing are transforming industries in ways we never imagined a decade ago. As the technology continues to advance, the possibilities are virtually endless. From healthcare to manufacturing, aerospace to fashion, 3D printing is making production faster, more efficient, and more customized. With the ability to reduce waste, lower costs, and bring innovative products to life, 3D printing is shaping the future of how we create, build, and design across a wide array of industries.